Contact Us

Find Us On Social Media

How To Take Care Of Your Wood Floors?

Get advanced knowledge on how to take care of your wooden possesions like floors and pergolas

Stay updated about new wood care techniques and methodologies

Answer most of your questions about wood floors and other items

In-home and office interior designs, the value of wood cannot be denied its timeless

visual appeal and natural beauty.

If you take proper care of wood floorings,

cabinets, installments, and claddings, you can expect them to survive for decades.

Let's take a look at the top ways to take care of your wood floorings and cabinets.

Wooden Floors Can Be The Highlight Of Any Home.

The Natural Strength And

Beauty Of Wood Has Been Used For Centuries And To This Day, Remains The Material Of

Choice For Flooring.

If You’ve Stripped Back An Old Victorian Floor, Had New Solid

Wood Or Engineered Flooring Installed, Or Even Used Reclaimed Boards, Looking After

And Maintaining Them Once They’ve Been Oiled Or Varnished Is Key.

It’s A Simple Fact

That Wooden Floor Finishes That Have Been Well Maintained Will Look Better And Last

Much Longer Than Those That Have Not.

So, What Is The Best Way To Look After And

Maintain A Wooden Floor? Well, You’ll Be Pleased To Know That It’s Not That

Difficult And Doesn’t Require A Great Deal Of Work.

To Help We’ve Produced A Lovely

Guide To Help You Keep Your Wooden Floors Looking Amazing

Wood is a beautiful option for your outdoor flooring or pergola. Teak wood especially is very durable and has high resistance to outdoor conditions, (sunlight, heat & rain) even when installed directly as a pool decking.

You just need to give it some attention to keep it as beautiful as day one. Here are some tips for outdoor wood care.

In this type of subfloor, wooden beams made of red pine wood with 5cm square section

or 5cm by 4cm rectangular section are installed with 25 to 35 spaces of concrete to

level the floor, fixed with metal fixtures and concrete to be bonded with the floor.

Then, 1.6cm by 10cm section of same wood type are installed with about 2-10 cm spaces

in opposite direction to be a top subfloor laid in which wood floor fixation takes

place.

This is the traditional subflooring, used more than 100 years ago, always used up

till now in nailed down installation technique.

In this type, we use concrete tiles, mosaic tiles, low quality ceramic tiles instead of wood for the leveling process, Tiles are installed regularly and flush on concrete, and wood Slabs of 1.6cm by 10cm or sheets of 10mm plywood are fixed on it, This method also is used for nailed down installation technique

Used always for glue down & floating installation technique, mosaic or ceramic tiles are installed directly using concrete, for leveling then wood floors are glued down on it, or floated on it using polyethylene sheets to proof humidity, temperature, and sound.

The most common & traditional way to install wood floors, wood tiles, or planks are to

be installed by nailing them down on wooden subfloors, the nails are inclined 45 degrees not vertical,

passing from the woodside directly fixing it to the subfloors a drum noise is heard

while walking on due to space empty spaces under the wood floor.

Bonding the wood floors with the subfloors using the glue-down technique is a very good and cheap way

to install your wood floors.

using polyurethane (oil-based) D4

glue or D3 water-based glue is the best way to ensure a lifelong bond, as the glue can dissipate

shear stress resulting on it because of the different expansion coefficients between the wood & the

concrete tiles or ceramic tiles.

no drum noise is heard at all, You will get a

lifetime guarantee against debonding when purchasing from The Wood Court.

Installing your floors using this technique makes them very easy to maintain as you can replace any damaged piece easily, the wood floors are floated over the subfloor, polyethylene sheet with 2mm thickness is placed between the wood & subfloor to isolate moisture and decrease sounds when walking on., This technique also makes it very easy to uninstall your wood floor and use it again in another place, leaving the subfloor without any damage.

Traditionally, you choose site-finishing when time isn't critical, new construction

and nobody lives on site (to avoid dust) it takes a long time, (4-6) days to send

and clean wood floors, ensure the site is clean, the environment is stable within

site, applying stain, sealing and top coating (about 3-4 coats), and wait for each

application to dry

Remember, no one can go through the site during the whole process, the smell of

finishing is not pleasant at all.

-Offensive odor

-Not expensive (moderately expensive)

-Multiple coats are needed to achieve a good finish

-Needs 3-5 days to walk on after application

Less odor

-More expensive

-More durable

-Dry faster (8-12 hours)

-Odor less

-Very expensive

-It-Easier to repair

-Walk on after 24 hours

-The finish stays consistent over time

-Healthy and environment friendly

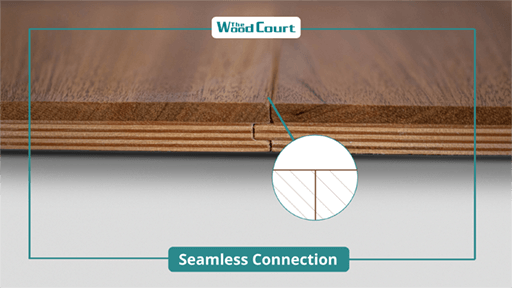

When you get site-finished floors you get the seamless look, however, with weather swings, gaping from high temperature, humidity, to low & vice versa, this option fade away, as wood is a living product, it expands and contracts to lead to visible joints

In the last 25 years, prefinished floors started to grow, as hardwood floors manufacturing become more technical in this case, the floor finishing is part of the manufacturer's job, & the product shipped to your home is fin1ished and ready to be installed.

When the floor manufacturer finished the floor, he use special finishing lines,

which create a perfect environment to apply powerful chemical sealers such as

aluminum & titanium oxides embedded in a UV-cured urethane coat.

The result is harder than anything applied on-site, the finish lasts longer & carries a better

warranty for the homeowner

Easier installation:

Requires no sanding, no staining, no sealing, no top coating, all are pre-done in our

factory you just need your floors to be installed then you can walk on immediately!

Easier maintenance:

Due to the durable finish, you will not need to refinish your floor for a long time,

however, you can easily replace damaged pieces, or refinish with sanding & coating

as if you have installed site-finished floors.

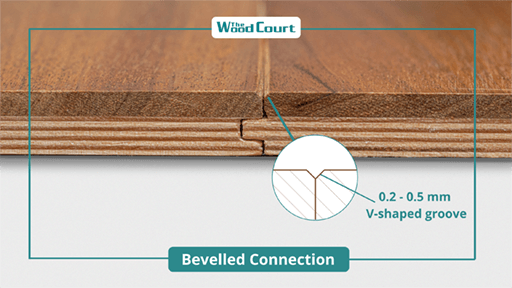

Pre-finished floors have beveled edges, not square ones, not like site-finish which

can have either square edges or beveled ones

It is the process in which the coat changes from liquid state to solid state under

ultraviolet rays instantly in a sealed finishing line, no no dust will stick to planks, so it results in a smooth

surface unlike site finish which is very hard to prevent very fine dust from

sticking to floors daring the long curing time and open environment

For site- finish, irregularity of subfloor is not a big problem as sending process

is enough to regulate the surface

In the care of prefinished floors, you need to ensure a perfectly flat subfloor

surface since you haven't the option of site-sanding

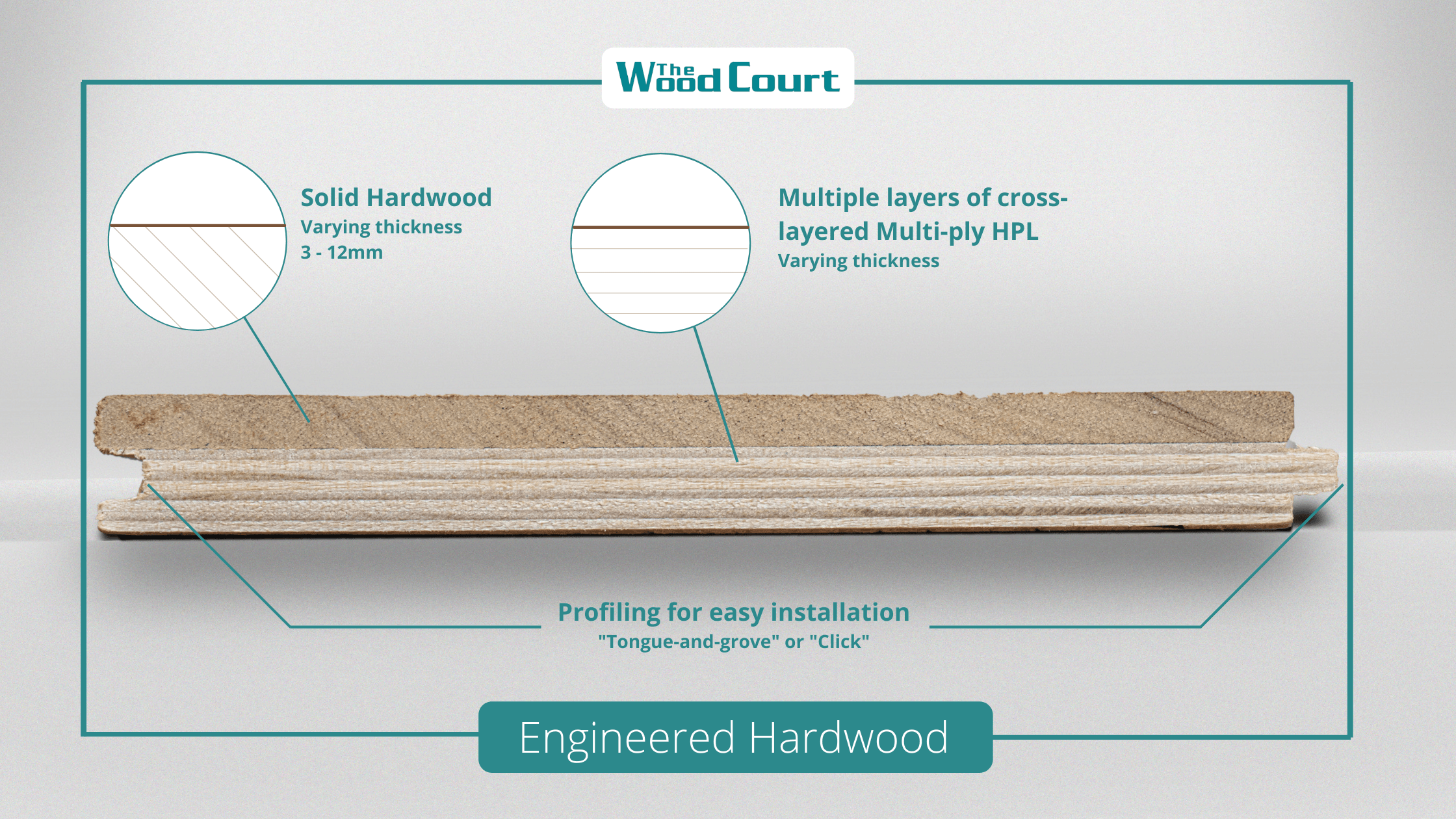

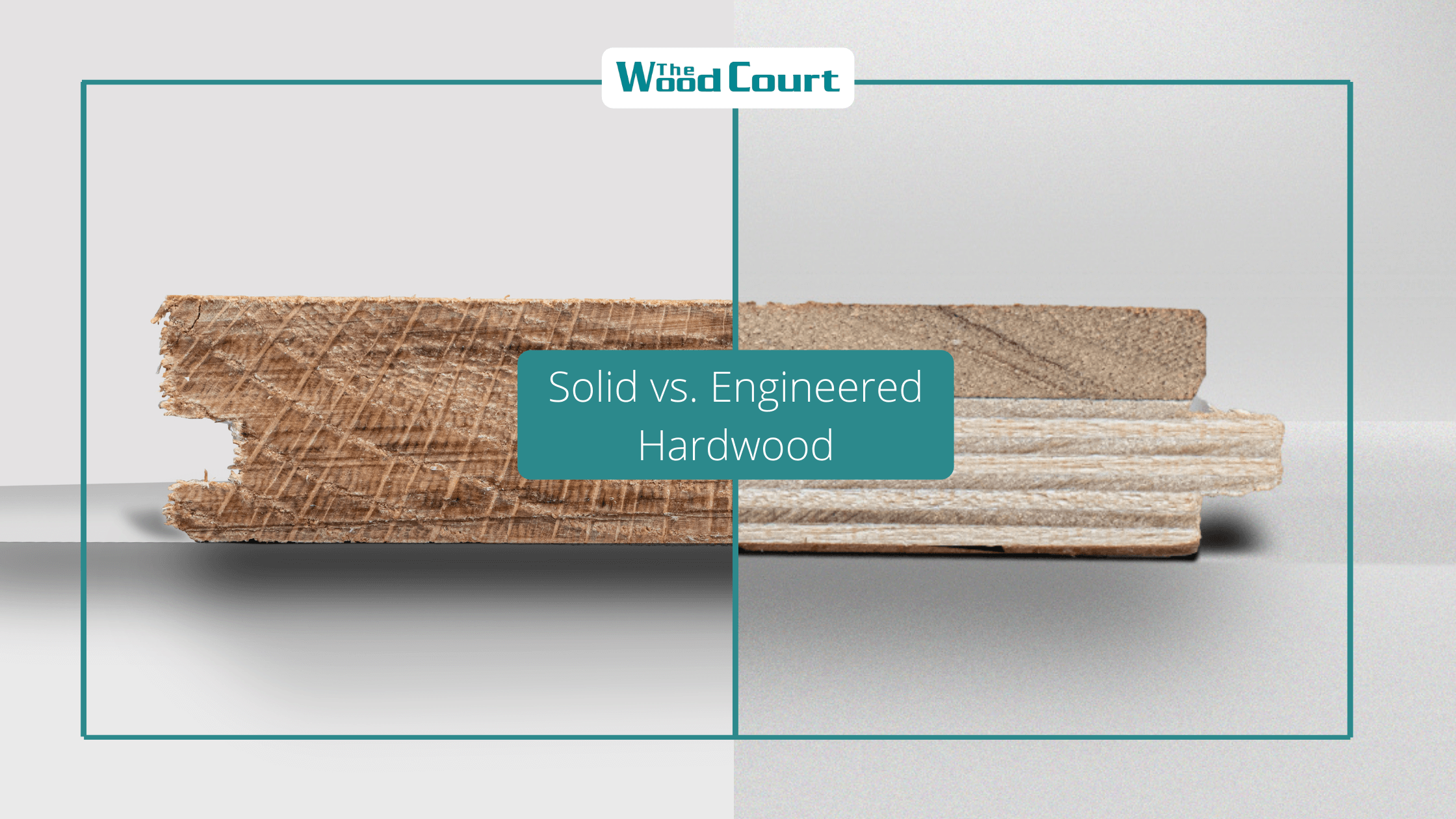

The word (engineered) before hardwoods is to indicate that the floor planks are made of multilayers

A. Base Layer

B. Top Layer

The base layer is consisting of about 7-9 layers of plywood each layer is bonded with the previous one anty-grained [the grains each layer is 90° rotate to the previous one]

this method gives very high dimensional stability and makes the planks also to be installed over any leveled subfloors.

The top layer is the expensive wood type, it is bonded to the base layer under high pressure (about 5 kg/cm) and 70°c temperature, this layer can be sanded and re-coated several times [up to more than 6 times] according to its thickness 4,6 or 9 mm.

Now we can say engineered wood flooring has more dimensional stability, and less deformation in shape when exposed to high/low temperature or humidity because of the anti-grained bottom layer.

You can ask for prefinished engineered flooring in which coating is a manufacturer in

the factory, not by the installer on site

This operation is done using very high coating technology [uv] technology, as they

protect are coated with polymers which change from liquid state to solid state under ultraviolet rays,

this finish is more durable and smoother, and the whole operation is done in sight special coating line in the factory.

At least (2) sealing coats, and (1)) layer of (anti-scratch) topcoat are applied to

planks, in addition to a staining layer (if needed) which is applied on

wood before applying the bottom and top layers, so it is guaranteed that under bad

usage, the color not able to be removed.

| Wear layer The layer above the tongue and groove |

4,6,9mm as per request can be renewed several times ace to wear layer thickness |

From [6-9] mm upon request can be renewed several times over to wear layer thickness |

|---|---|---|

| Durability | Excellent | Very good |

| Maximum width of plank | Up to (30)cm | Up to (15)cm |

| Pre Finish | Present can be installed pre-finish with all installation Tech |

Absent can't be installed pre-finished except in very rare conditions |

| Installation technique | Floating Gluedown Nailed |

Gluedown Nailed |

| Time to install 100 ㎡ | 8-12 hours Only two technicians with hand tools |

80-100 hours using at least Four technicians, With hand tools & special machines |

| Maintaining | Easy to maintaining and replace pieces cleaning & Fast | Moderate to hard maintaining , with adhesives and chemicals which needs site to be empty |

They offer an elegant and timeless look that never goes out of style.

They also enable a look of spaciousness and lend a warm and

authentic feel wherever they’re installed.

Wood flooring offers a variety of appearances; from grain patterns

to colors, stains, and designs.

The floors are easy to clean as they do not accumulate a lot of

dirt, dust, and debris.

Wood floors have long-term durability and can last for generations.

They are a great long-term investment and can increase the value of

your property.

Properly installed wood floors increase and improve acoustics in the

room; suitable for music rooms and concert halls.

A healthy floor choice for allergy sufferers.

Wood floors are relatively easy to clean and maintain and can live in

harmony with pets.

However, they are vulnerable to scratches — hence

choosing a harder species of wood makes it possible to enjoy your

gorgeous floor without stressing about your pets.

A rustic or distressed finish is particularly a good option since it

easily hides signs of everyday wear and tears.

Alternatively, you may

want to select wood flooring with a lighter color and lower gloss

level to help hide additional marks that may occur.

Also trimming your pet's nails regularly will help.

Wood is a natural material, each plank features unique details and

therefore, you should expect there will be natural color variations.

Most people love these slight variations for added character and

charm that they offer.

The higher grade of wood flooring tends to

feature a more uniform color and minimal character marks whilst a

lower grade of flooring contains distinct variations in color.

Engineered woods have a variable top layer thickness compared to

solid wood.

Engineered floors can be refinished — and the

thickness of the top layer is the major factor contributing to this.

Here in the wood court, we manufacture a 9mm thick top layer that

can be sanded and refinished like as solid wood.

Yes, it’s possible.

If you want to install your floor over ceramic

tiles, a glued-down methodology, or floating are the available methods

choosing the suitable method is depending on the type of wood floors

you want to install, either engineered wood or solid wood, also

depends on the finish type, prefinished or site finish, dimension of

needed blanks may be a factor, you can contact the wood court and

take professional advice.

Gapping is fairly normal during the winter season due to changes in

humidity of the room which causes wood to dry out and shrink.

To

combat the issue, use a humidifier during the winter months to keep

your home within the required temperature — as long as the humidity

level is between 35-50%.

Depending on your wood selection, certain species tend to contract

and expand more than others.

Using an engineered wood floor will reduce the appearance of gapping

as it is more dimensionally stable than solid wood

In some instances, wood can be glued down over existing floors such

as laminate, vinyl, wood floors, and even some types of tile.

The existing floor has to be relatively smooth, free of major

imperfections, and fully adhered to the sub-floor.

The installer must follow the manufacturer's recommendation.

No, The thicker and better quality engineered woods will last for

years and years and can be refinished once or twice.

Also, the technology and factory-applied, UV-cured urethane finish

with melamine that is used today by the wood court make a tough &

durable finish and is available on both engineered and solid wood

floors.

Engineered and solid wood floors.

Engineered wood floors are also

much more dimensionally stable than solid hardwood flooring so they

can be used in many situations where solid wood is not

recommended.

Click Here To Learn More About The

Difference Between Engineered And Solid Wood Floors.

Today's wood floors do not require a paste wax to the finish and

paste waxes should not be used.

Most hardwood floors today have some

type of urethane finish and will cloud up and become sticky if a

paste wax is applied to the finish

The prefinished hardwood floor is sealed with multiple coats of finish at the factory.

The finish coats typically contain aluminum oxide, the second hardest substance next to diamond, to provide a hard-wearing protective finish.

Unfinished flooring must be finished on site after installation takes place.

Aluminum oxide cannot be used in the finish on-site because the longer drying time causing the aluminum oxide particles to sink to the bottom of the finish.

Site-finished floors usually are better at protecting against above floor moisture.

Engineered hardwood floors can be floated, but not solid hardwood floors, due to high expanding and contracting coefficient of solid wood floors, and bad dimensional stability

Moisture can cause many different problems for a hardwood floor, such as cracking, cupping, and crowning

. Over time, excessive moisture will destroy a wood floor, so it is suggested not to use water to clean the hardwood floors and mop up spills immediately.

click here to learn how to take care of your wooden floors

There is water caught between the wood flooring and the subfloor if

crowing or

cupping

occurs.

Crowning is when the centerboards are higher than the outer boards.

Cupping is when the outer boards are higher than the centerboards, it also

if any

moisture

marks found on any of your walls, sudden black stains on the wood floor

surface

started to

appear in some areas, if you saw any of these, its time to call an

expert

Well, it depends, if you will install prefinished wood floors, then the perfect time for installing is the high end when every single technician is out of your home expect the painter, you may need a painter to fill gaps between the skirting and the wall (if founded) but if you purchased site finish floors, you have to install them a bit earlier, but do not finish immediately after installation, minimum of 7-12 days are needed before site finishing to let the wood floors react with site conditions, wood moisture and temperature reach an equilibrium state, also in case of glued down installation technique, it needs time to ensure the glue has dried and cured.

Use plastic, foam, or felt discs under all the furniture legs..

These can be purchased at many retail stores, and are designed not only to reduce or prevent scratching but also to reduce or prevent movement of the furniture altogether.

Laminate flooring is an excellent choice when the look and feel of real wood are desired, but the cost is a major concern.

Part of the overall cost savings derived from installing laminate is in labor.

Almost anyone can install a laminate floor and get professional results.

Laminate flooring is an excellent choice for high-traffic areas and where damage from pets is a concern.

It is also an excellent choice for many commercial applications where scratch damage is a major concern.

Versatility is another factor to consider when choosing laminate.

If you aren’t trying to get the look of wood, laminate offers stone, metal, and ceramic patterns as well..

When you need to have real wood, there is no substitute.

Engineered hardwood gives you the beauty of solid wood and the stability of cross-grained construction

Discerning clients will demand real hardwood when shopping for a new home and if resale value is a concern, hardwood flooring will give you the highest return on investment.

While there are many fine, durable, beautiful kinds of wood, none hold a candle to teak..

Teak has a very high natural oil content which makes it almost decay-resistant, which is something that no other wood can boast.

Because of the high oil content, teak is essentially waterproof and does not crack or warp due to damp climates.

Teak is resistant to termites and other wood pests, which makes it ideal for projects that are usually vulnerable to termite infestation

Teak also gets to brag that it doesn’t crack or turn colors when exposed to metals, which makes it great for building long-lasting furniture.

Teak wood has been used to build boat decks — rather, battleships — for centuries because of its water resistance and strength.

Today, teak is used anywhere that any other wood is, and is popular for creating bath, spa, pergolas, and pool furniture because it allows the natural look of wood without the weathered appearance or swelling that other woods take on when exposed to humid environments.

Hardwood Flooring really makes your home very welcoming & beautiful. When properly cared for, it will stand for a long time giving you warm & positive feelings.

View More

Do you love the feel of natural wood on floors? If yes, here's how to choose the right hardwood floor for your home.

View More

Many people are put off the idea of teak decks by many of the horror stories that circulate. In reality, there is no reason to be frightened off and if looked after and cared for correctly they can be cared for with minimal hassle and cost.

View More.jpg)

High-Pressure Laminate or HPL is the direct descendent of the original plastic laminate. It is considered to be one of the most durable decorative surface materials and is available with special performance properties including chemical, fire and wear resistance. Special grades of HPL can be post-formed around curved edges by application of heat and restraint.

View More